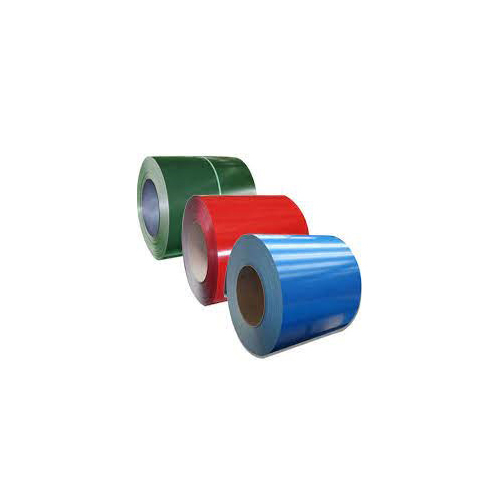

Ppgi Coils

95 INR/Kilograms

Product Details:

- Color All Color

- Product Type Ppgi Coils

- Size Standard

- Usage Industrial & Commercial

- Material Other

- Technique Other

- Grade Industrial

- Click to View more

X

Ppgi Coils Price And Quantity

- 95 INR/Kilograms

- 5 Ton

Ppgi Coils Product Specifications

- Standard

- Other

- Industrial & Commercial

- Industrial

- All Color

- Other

- Yes

- Yes

- Ppgi Coils

Ppgi Coils Trade Information

- 100 Ton Per Day

- 05 Days

- All India

Product Description

PPGI stands for PrePainted Galvanized Iron it refers to a type of steel product that has been coated with a layer of paint or resin before being formed into the final product Heres a detailed description of PPGI

Base Material PPGI starts with a base material of galvanized steel GI which is coated with a layer of zinc to protect it from corrosion Galvanized steel is chosen for its excellent corrosion resistance and durability

PrePainting Process The galvanized steel undergoes a prepainting process where a layer of paint or resin is applied to both sides of the steel coil or sheet This process is often done using techniques such as coil coating where the steel coil passes through a series of rollers to evenly apply the paint or resin

Color and Finish PPGI is available in a wide range of colors and finishes to suit different aesthetic preferences and applications The paint or resin layer can be customized to achieve specific colors gloss levels and textures ranging from matte to highgloss finishes

Corrosion Resistance The combination of the zinc coating and the paint or resin layer provides enhanced corrosion resistance compared to bare steel This makes PPGI suitable for outdoor applications and environments with high humidity or exposure to harsh weather conditions

Formability PPGI retains the formability and versatility of the base galvanized steel material allowing it to be easily shaped and formed into various products such as roofing panels wall cladding gutters and other building materials

Applications PPGI is widely used in the construction industry for roofing siding and architectural panels due to its durability aesthetic appeal and corrosion resistance It is also used in the manufacturing of appliances automotive parts and other consumer goods

Environmental Considerations PPGI coatings are typically formulated to meet environmental regulations and standards such as low volatile organic compound VOC emissions and heavy metal content restrictions

Overall PPGI offers a durable and versatile solution for a wide range of applications where corrosion resistance aesthetic appeal and longterm performance are important factors It provides the benefits of both galvanized steel and paint coatings combining strength and protection with customizable colors and finishes

SPECIFICATION

Coating Thickness The thickness of the paint or resin coating applied to the galvanized steel substrate is specified in terms of coating weight usually measured in grams per square meter gm2 or micrometers m Typical coating thicknesses for PPGI can range from around 15 m to 35 m or more depending on the application and performance requirements

Paint System The type of paint system used for PPGI coatings can vary including polyester PE polyvinylidene fluoride PVDF silicon modified polyester SMP and others Each paint system offers different levels of durability weather resistance and color retention

Substrate Thickness PPGI coils or sheets are available in various thicknesses typically measured in gauge or millimeters mm Standard thicknesses for PPGI substrates can range from around 02 mm to 12 mm or more depending on the application and structural requirements

Width PPGI coils are supplied in standard widths ranging from around 600 mm to 1500 mm or more depending on the manufacturers capabilities and customer requirements

Base Material PPGI starts with a base material of galvanized steel GI which is coated with a layer of zinc to protect it from corrosion Galvanized steel is chosen for its excellent corrosion resistance and durability

PrePainting Process The galvanized steel undergoes a prepainting process where a layer of paint or resin is applied to both sides of the steel coil or sheet This process is often done using techniques such as coil coating where the steel coil passes through a series of rollers to evenly apply the paint or resin

Color and Finish PPGI is available in a wide range of colors and finishes to suit different aesthetic preferences and applications The paint or resin layer can be customized to achieve specific colors gloss levels and textures ranging from matte to highgloss finishes

Corrosion Resistance The combination of the zinc coating and the paint or resin layer provides enhanced corrosion resistance compared to bare steel This makes PPGI suitable for outdoor applications and environments with high humidity or exposure to harsh weather conditions

Formability PPGI retains the formability and versatility of the base galvanized steel material allowing it to be easily shaped and formed into various products such as roofing panels wall cladding gutters and other building materials

Applications PPGI is widely used in the construction industry for roofing siding and architectural panels due to its durability aesthetic appeal and corrosion resistance It is also used in the manufacturing of appliances automotive parts and other consumer goods

Environmental Considerations PPGI coatings are typically formulated to meet environmental regulations and standards such as low volatile organic compound VOC emissions and heavy metal content restrictions

Overall PPGI offers a durable and versatile solution for a wide range of applications where corrosion resistance aesthetic appeal and longterm performance are important factors It provides the benefits of both galvanized steel and paint coatings combining strength and protection with customizable colors and finishes

SPECIFICATION

Coating Thickness The thickness of the paint or resin coating applied to the galvanized steel substrate is specified in terms of coating weight usually measured in grams per square meter gm2 or micrometers m Typical coating thicknesses for PPGI can range from around 15 m to 35 m or more depending on the application and performance requirements

Paint System The type of paint system used for PPGI coatings can vary including polyester PE polyvinylidene fluoride PVDF silicon modified polyester SMP and others Each paint system offers different levels of durability weather resistance and color retention

Substrate Thickness PPGI coils or sheets are available in various thicknesses typically measured in gauge or millimeters mm Standard thicknesses for PPGI substrates can range from around 02 mm to 12 mm or more depending on the application and structural requirements

Width PPGI coils are supplied in standard widths ranging from around 600 mm to 1500 mm or more depending on the manufacturers capabilities and customer requirements

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free